Model No.︰PM2-150CPYQ

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 4500 / pc

Minimum Order︰1 pc

The color registration principle of the pad printing machine is relatively simple, which is to position the product with a jig, and then use different rubber heads to print different colors. For the shuttle pad printing machine at the workbench position, there is only one jig. It is more convenient to switch between positions, but some products are not easy to make fixtures for positioning, such as cloth and leather. Some product fixtures are difficult to position accurately, such as mice and some flexible toys. At this time, it is more convenient to choose a pad printer with a rubber head shuttle. The product of the pad printing machine with the rubber head shuttle is fixed, and the rubber head shuttles over the product after dipping the ink for overprinting. Since there is no tolerance for fixture manufacturing and position error during movement, the overprinting accuracy will be further improved.

Glass wine glasses

Glass wine glasses are usually made of soda-lime glass or crystal glass. Soda-lime glass is low-cost and suitable for daily use; crystal glass contains lead or zinc and other components, has higher transparency and glossiness, feels heavier, and is mostly used for high-end wine glasses. Its shapes are diverse, and the common ones are tulip-shaped, flute-shaped, Bordeaux-shaped, etc. Different shapes are suitable for different types of wine. For example, the tulip-shaped is suitable for tasting wine, which allows the wine to fully contact with the air and release aroma.

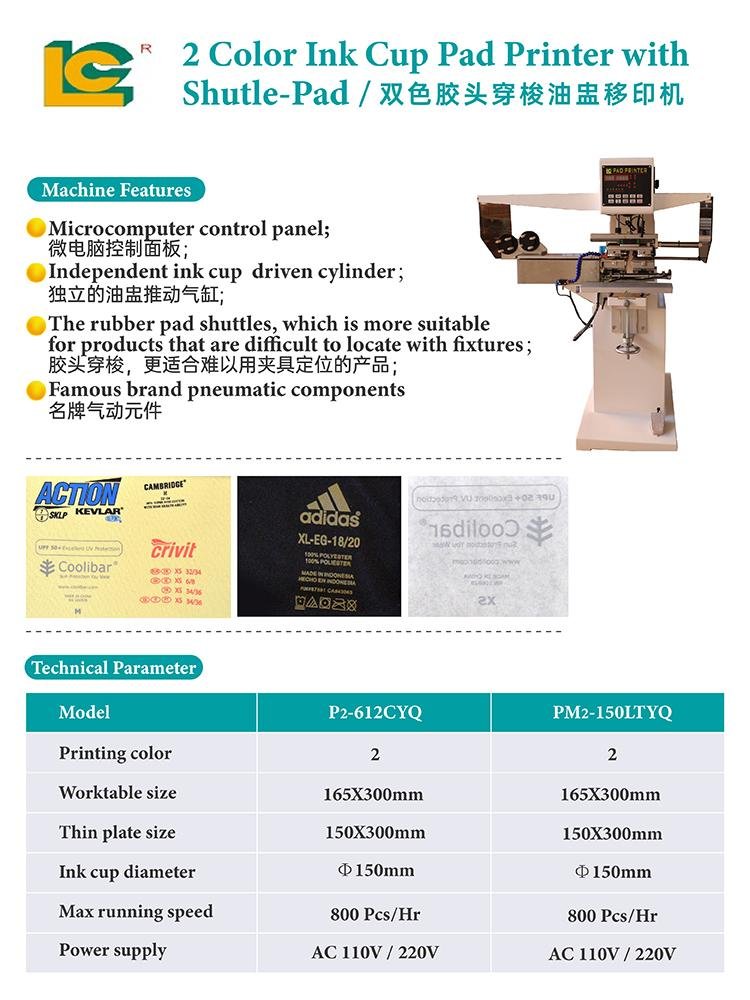

Pad shuttle two-color shuttle oil cup printer

• Principle: The machine has two oil cups, each containing different colors of ink. During printing, the rubber head shuttles between the two oil cups, first absorbing one color of ink from one oil cup and printing it on the glass wine glass, and then moving to the other oil cup to absorb another color of ink for secondary printing, in this way to achieve two-color printing.

• Structural composition: It is mainly composed of oil cups, rubber head shuttle mechanism, workbench, operation panel, etc. The ink cup is used to store ink; the pad shuttle mechanism drives the pad printing pad to move gradually between the two ink devices to achieve color registration; the workbench is used to install fixtures and corresponding products; there are patterns or texts to be printed on the printing plate; this pad printing machine is suitable for printing exquisite two-color patterns on glass wine glasses or other corresponding products, improving the beauty and added value of the products.

|

Two colors Cloth-label pad printer//Structure |

|

|

Working table |

Standard working table |

|

Pad Shuttle stroke |

200mm |

|

Ink supply system |

Closed -type system |

|

Plate type and size |

10mm Thick steel plate. |

|

Pad dropping control |

Double -cylinder , Indenpendent pressing |

|

Ink drying |

Heat air |

|

Two colors cloth-label pad printer//Usage and characters |

|

|

Guide |

|

|

Application fields |

Garment, Cloth, Label, Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

Two colors cloth-label pad printer //Parameter |

|

|

Technical parameters |

PM2-150LTCPYQ |

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Two colors cloth label pad printer //Advantage |

|

|

Function |

|

Summary︰

There are two types of two-color shuttle pad printers: One is shuttle on the worktable. This kind of pad printer is more common. The worktable will move left and righth between the two printing positions to complete the overprint of the two colors. The other is a shuttle type pad printer with rubber heads. The product remains on the worktable while the two rubber heads shuttle left and right to achieve two-color overprinting.

The workbench shuttle type pad printer is more suitable for products that are three-dimensional and easy to be positioned with fixture, while the rubber pad shuttle type pad printer is more suitable for cloth or products that are not easy to position with fixture.