|

|

|

|

Flame treatment machine

Model No.︰

SF250C

Brand Name︰

LC

Country of Origin︰

China

Unit Price︰

US $ 2538 / pc

Minimum Order︰

1 pc

Product Description

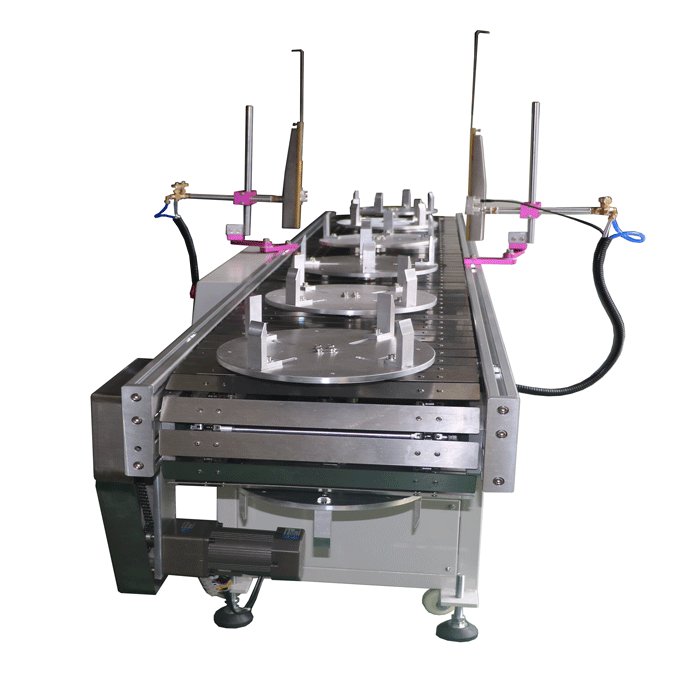

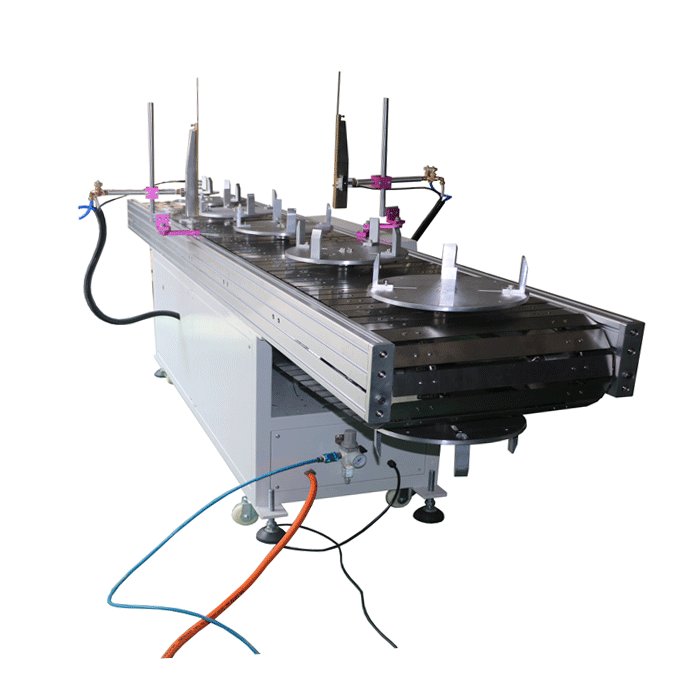

Flame treatment machine for plastic barrels with a diameter of 300 mm:

Conveying device

Usually, a conveyor mesh belt is used, which is driven by a reduction motor to rotate. The conveyor mesh belt can smoothly transport the plastic barrel forward to ensure the continuity of the flame treatment.

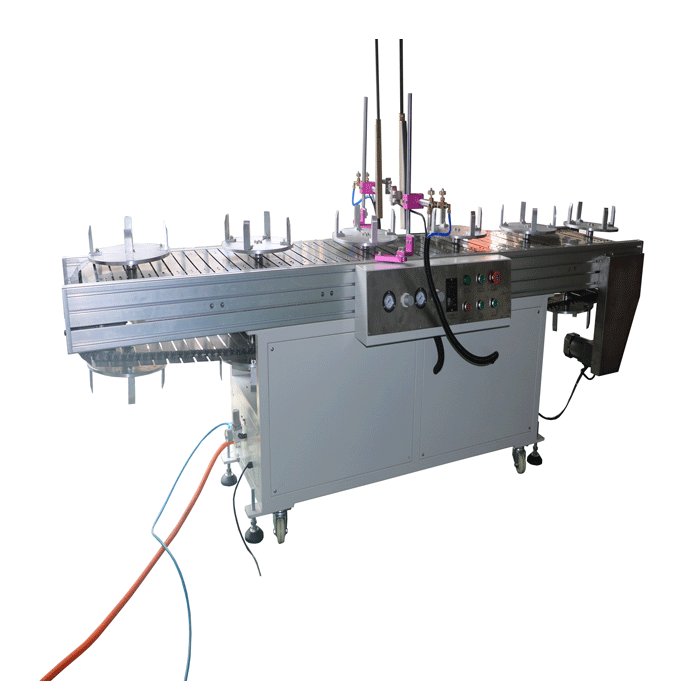

Flame generating device

Including gas supply system, burner, etc. The gas supply system provides fuel, and the burner mixes the gas with air and ignites it to produce a high-temperature flame. The flame nozzle of the flame treatment machine is connected to the gas and compressed air, which usually produces a flame with a higher airflow. The outer flame of the flame is blue and has the highest temperature. The surface of the treated plastic barrel should be located in the outer flame area.

Rotating device

In order to make the flame treatment on the surface of the plastic barrel more uniform and increase the treatment area, the flame treatment machine is equipped with a rotating device. For example, a hollow base is fixed on the top of the frame, and the driven gear in the base is driven to rotate by a rotating motor.

Positioning device

To ensure that the position of the plastic barrel is fixed and the rotation is stable during the flame treatment, a common method is to set a transmission positioning device on the conveyor belt, such as a rotating motor connected to a flywheel through a rotating shaft, the flywheel drives the transmission wheel and the positioning pile to rotate, and the mouth of the plastic barrel is inserted upside down on the positioning pile, which can rotate with the positioning pile to ensure that all sides are evenly exposed to the fire.

Control system

Includes electrical control system and temperature control system. The electrical control system can realize the control of the conveying device, rotating device, igniter, etc., and the temperature control system can monitor and adjust the flame temperature to ensure the quality and stability of the flame treatment.

|

SF250C Cylinder bucket Flame treatment Machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

SF250C Cylinder flame treatment Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

SF250C Cylinder bucket Flame treatment Machine//Advantage |

|

|

Function |

|

Polyolefin material has excellent chemical resistance and good processing properties, which is why it is used as the main container manufacturing material. However, polyolefin materials are non-polar molecules with low surface tension and poor affinity for ink, so the printability is not good, and the ink is easy to fall off. For this reason, polarizing the surface of the polyolefin material becomes a pre-press treatment An important step, there are many methods for polarizing treatment at present: flame treatment, high frequency treatment, plasma treatment, and chemical oxidation treatment. Flame treatment is the most effective and simplest method for polarizing container polyolefin materials. When you buy a semi-automatic screen printing machine and find that the ink adhesion is not good, you may wish to consider the flame treatment procedure. Nowadays, many users buy fully automatic screen printing machines, which basically regard flame treatment as standard configuration, so you don't need to worry too much.