Thermal Transfer Test

Heat transfer factors

Thermal transfer printing and bronzing are two processes with completely different literal meanings but are actually difficult to distinguish. The domestic definition alone is very complicated. According to the general definition, the machine that uses hot stamping film is called hot stamping machine, and the machine that uses heat transfer film is called heat transfer machine. Thermal transfer film is an intermediary film with rich graphics and text printed by gravure printing machine, screen printing machine or inkjet printer. It is pressed on the surface of the product by rubber rollers on the thermal transfer printing machine to complete the transfer.

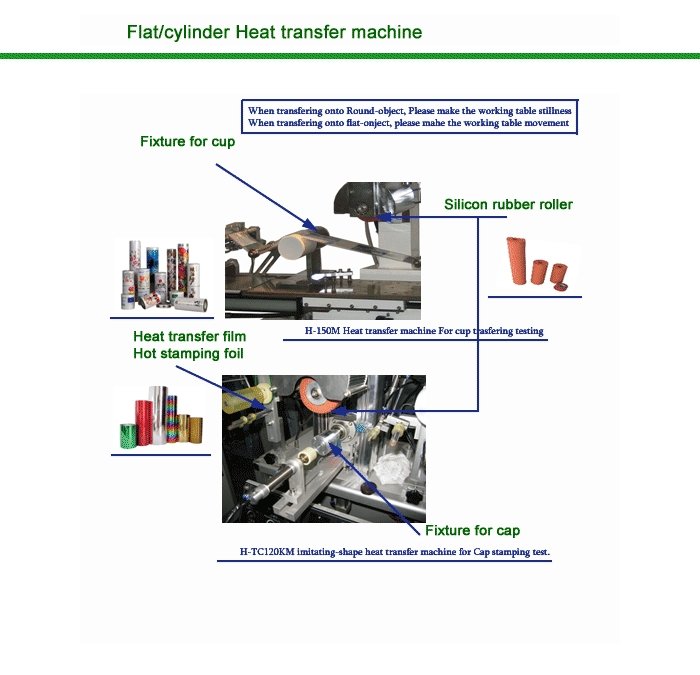

The printing elements of thermal transfer printing include fixture, thermal transfer film, silicone roller or silicone plate. Since the patterns on the heat transfer film are often independent patterns one by one, the heat transfer machine often needs an electric eye tracking system. Therefore, some people in the industry call the hot pressing equipment installed with the electric eye tracking system a heat transfer machine, while the hot pressing equipment without an electric eye tracking system is called a bronzing machine.

Obviously, it is difficult to distinguish between heat transfer printing machine and bronzing machine. Maybe we can easily distinguish between hot stamping process and heat transfer printing process.

What you need to consider in the heat transfer printing elements is to make a suitable fixture, choose a heat transfer film that meets the customer's needs, and then install the silicone roller. Sometimes, the silicone roller needs to be ground into a special shape to complete the transfer well. print.

Heat transfer for taper cups

For the decoration of cups, it has always been the battleground for special printing processes. Due to the rich colors and expressive power of heat transfer printing, heat transfer printing technology plays an important role in the decoration of cups. For a cylindrical cup, its unfolded surface is a cuboid, which can be done well with an ordinary surface heat transfer machine, but for a cup with a considerable amount of taper, due to its large end and small end After the surface is unfolded, it presents a fan shape, so the transfer of the thermal transfer film will be unbalanced. The large end needs to turn over a longer arc length, and the small end needs to turn over a shorter arc length. In order to accurately transfer the thermal transfer film to the cup in proportion, a heat transfer machine specially used for tapered cups has been developed, which will be installed on the fan-shaped track mechanism according to the thermal transfer film. During the process, the thermal transfer film is rotated at different angles according to the arc lengths of the big end and the small end of the fan, and the pattern of the tapered cup is transferred very accurately.

Theoretically speaking, the cups have a certain taper. If you want to transfer accurately, you must use a taper transfer machine, but if the taper is not too large, you can also use an ordinary thermal transfer machine, but we have to accept the small The graphics and text are deformed.

The heat transfer machine for tapered cups is the same as the ordinary heat transfer machine. It needs to make a jig, and it needs the perfect cooperation of three elements: the heat transfer film and the silicone roller.