RFQ

What treating on Polyolefin with Flame?

Polyolefin materials, especially polyethylene, and polypropylene are the most common materials in plastic packaging materials. It has the advantages of low density, high strength, good flexibility, good corrosion resistance, and environmental protection. It is widely used in food, pharmaceuticals, and cosmetics. Manufacturing of hollow containers for daily necessities. Surface treatment of polyolefin materials before printing is the most common issue involved in the printing process.

The hydrogen bonding of the polyolefin material causes the olefin molecules to form a non-polar structure. This non-polar structure forms a repulsive unit on the surface of the material. The surface tension is low, which affects the penetration of the ink molecules. If the necessary surface treatment is not performed, the adhesion of the ink Focus will be affected.

There are many ways for the surface treatment of polyolefins. The better method for the treatment of hollow plastic containers, cups, hoses and other products is flame treatment. Flame treatment introduces oxygen atoms in the middle of olefin hydrogen bonds, thereby changing the surface structure of olefin molecules and thus Form polar groups, increase the surface tension of the material and improve the affinity of the ink.

Some PP special inks contain strong oxidants, which can play the role of penetration while oxidizing, and can not be treated with flame. However, there are many process variables in the manufacture of olefin materials, and flame processors are still the recommended option.

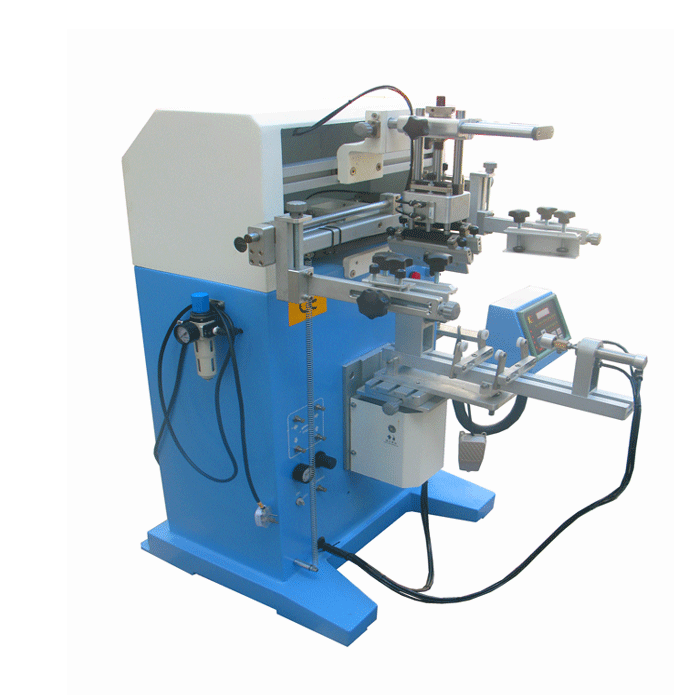

Cylinder screen printing machine

How to print a cylinder is nothing new. There are very many curved screen printers on the market to choose from. Its principle is to convert the rotation of the cylinder into the plane movement of the screen. The perimeter of the cylinder should be slightly larger than the distance the screen moves.

Through the limited upgrade of the curved screen printing machine screen system, fixtures and moving guides, the curved screen printing machine can also print oval and even shaped products.

what kinds of products can be printed?

The curved screen printer can print many types of products, but it is still mainly used to print the following products of the cylinder type:

1) Hollow plastic bottles are blow-molded bottles, which are often used to hold solid powders and liquids. This type of bottle has a small mouth and a large body, and can be made with a clamp for printing. For relatively soft bottles, the clamp also needs to be inflated. Filters, metal pipes and other products can be used without inflation.

2) Hose and cup. This kind of product has the same opening diameter as the bottle body, or is larger than the bottle body. It is very easy to make a plug-in support, and it can be printed without inflation.

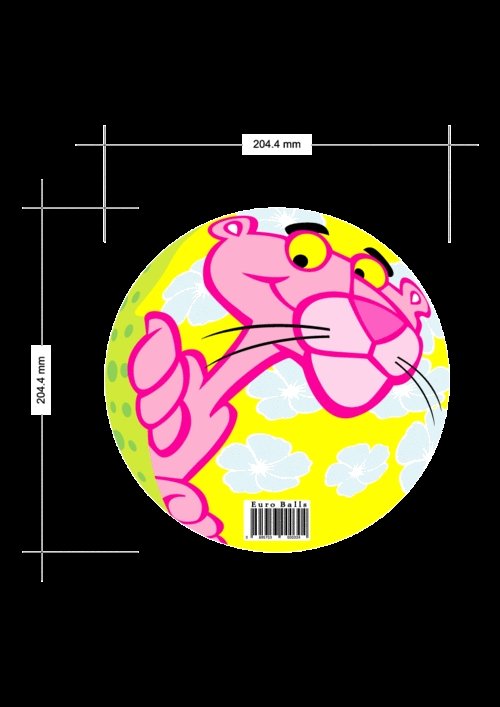

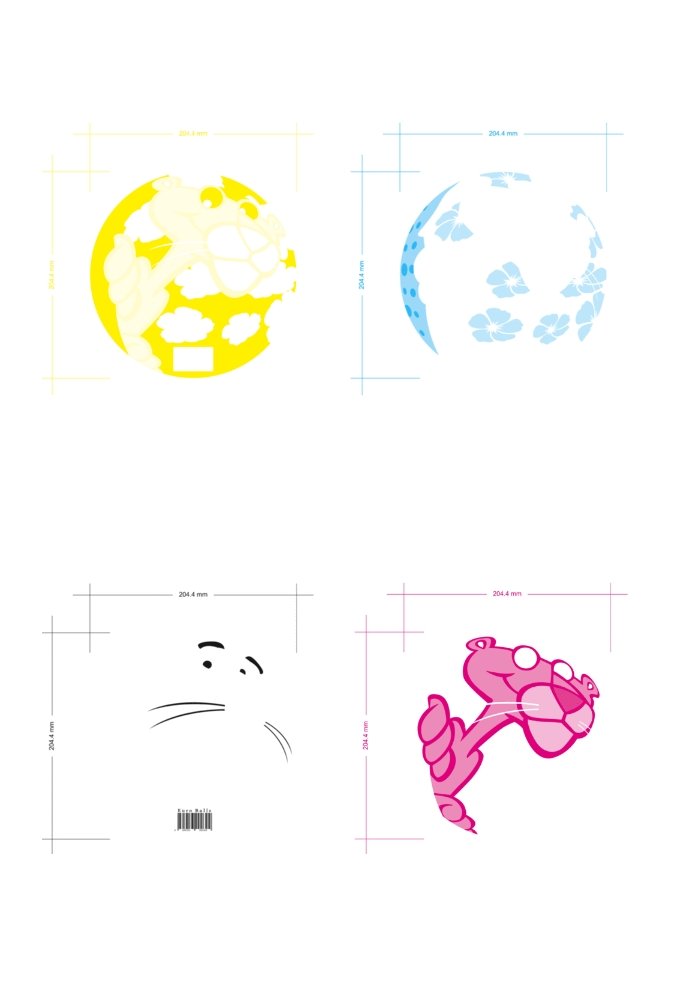

What is Printing color separation?

The icon is a four-color lines of the original, the user demands Pad printed onto the surface of the sphere. Pad of principles and other printed the same way, using the reprographic, and color over-printing process to copy the original. Line originals, using visual way to distinguish between the number of colors. Above the original is composed of red, yellow, blue, black color block design. Film Producer easily the original color separation and then output the following four monochrome artwork

Very simple!

Making pad printing plates with per film, a total of four steel plates;

Install the pad printing plate to the four-color pad printing machine , add ink, ink color corresponds to a different color steel plate. Lines of the original color usually need to deploy, modulated with Pantone color card color you need.

Pad overprint precision printing color sequence is also no uniform requirement, like your experience printing quality originals.

Why use Polymer plate by pad printer

European customers are very like the printing resin version. They always ask whether we can pad printing machine resin version.

Pad is actually a version of resin on the metal surface of the substrate sensitive adhesive coating is made of nylon, lithography to form a similar form of intaglio printing plate, printing plate as installed in the printing machine as used. Nylon inside the family is more wear-resistant plastic, but how can match the metal, so the printing resin version of the anti-Indian rate than steel.

However, for Europeans, this is not the most important, it is important that the following two points:

1) printing resin plate making process is safe, steel plate-making process takes into concentrated nitric acid or ferric chloride, which are oxidants, skin damage, resultant NO or NO2 is a great environment pollution;

2) printing resin plate making process there is no corrosion program, network losses is relatively small, fine lines and outlets in the graphic printing when a significant advantage. No wonder the Europeans prefer to use it without having to care about the cost of the resin version.

Currently, LC brands and the LC oil cup pad printing machine pad printer brand oil pan can be used all the resin version.

December 10, 2011, Australian customers order the TP1-408C is used 100 * 200mm resin version.

We sell to Africa Tunisia customers P1-408 oil pan color pad printer also uses a resin version.

How to exchange plain from round fuction?

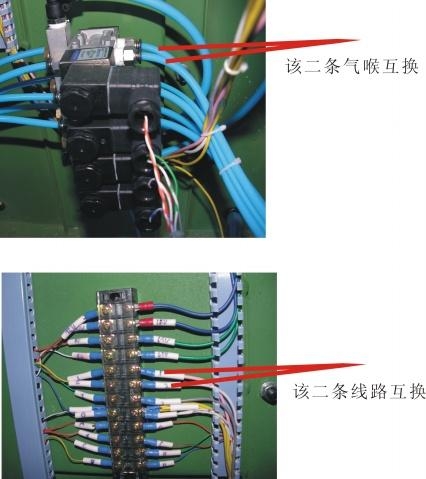

Most of the curved screen printing machines are designed to achieve both surface and plane functions: when the frame is stationary and the squeegee moves left and right, the screen printing machine performs the flat printing function; when the squeegee does not move left and right, the frame moves left and right. At the time, the machine realizes the surface printing function. Therefore, the following operations are required after the necessary modification of the curved screen printing machine:

1) LC brand screen printing machine adopts the method of replacing the position of the frame assembly and the scraper assembly to achieve the purpose: fix the scraper on the frame when the surface is silk screen, install the round surface workbench; Installed on the rack and installed a flat workbench;

2) Plane printing requires the squeegee to be pressed down, the ink slab is lifted, and the squeegee is moved to the left. After the printing is completed, the squeegee is lifted, the squeegee is pressed down, and then the squeegee is moved to the left. After the scraper is pressed down, the screen moves to the right. After the printing is completed, the scraper is lifted, and the frame is turned back to the left. For this reason, the circuit and the pneumatic circuit must be appropriately improved.

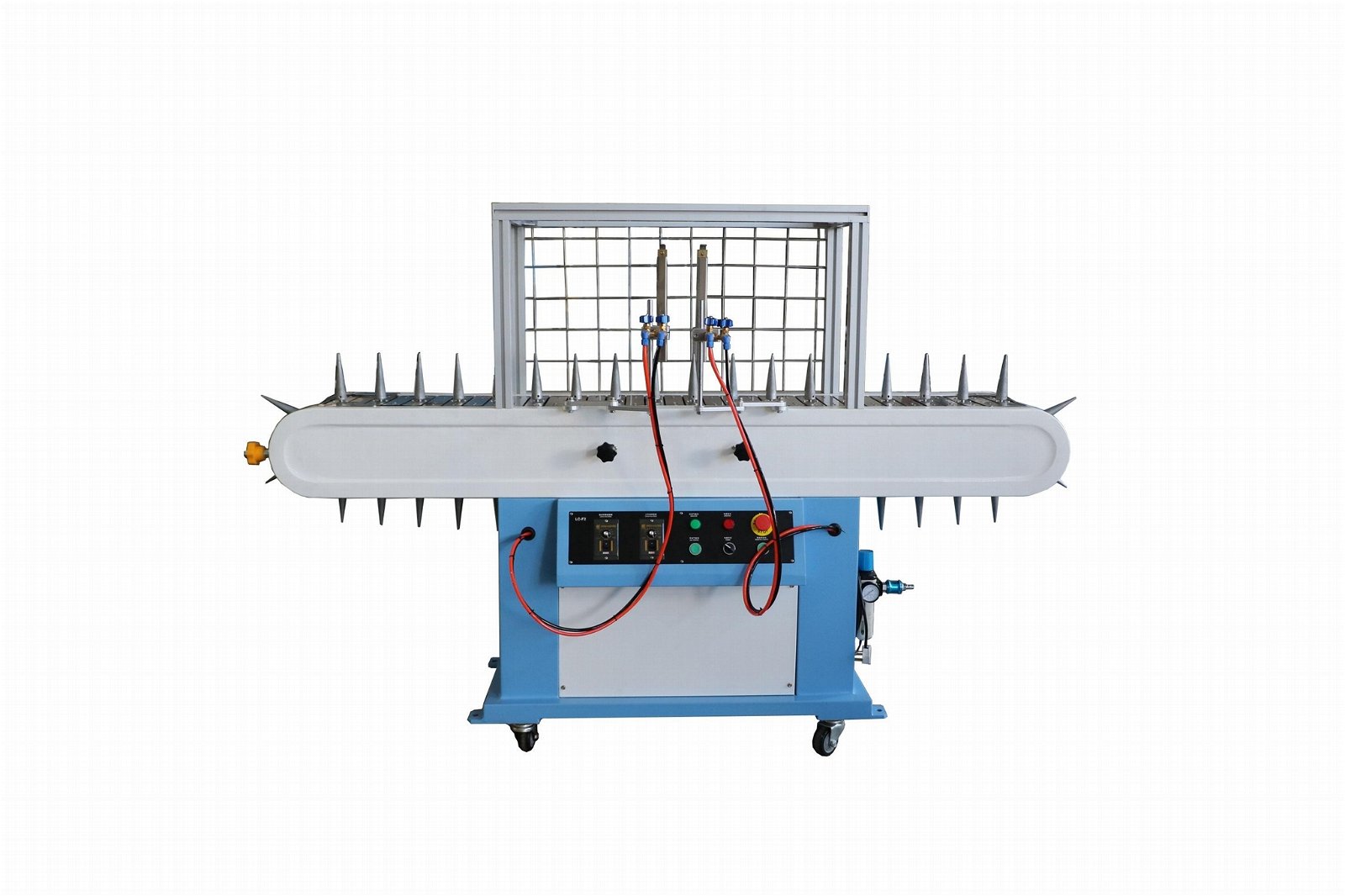

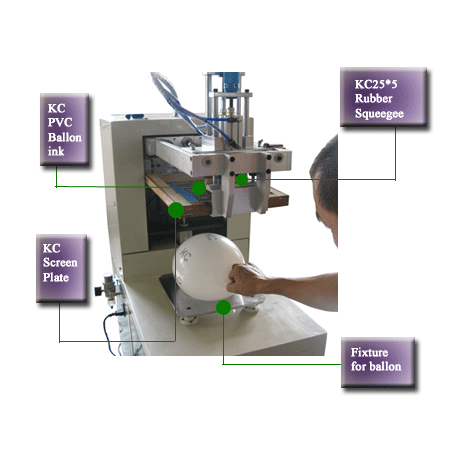

How to print balloon?

Balloon silk and silk products in general is slightly different, it must be a certain volume of the balloon blown before printing.

1) balloon printing machine table with round support, can support the balloon blow up after;

2) Because of the flexibility of the balloon, under the pressure will force the halftone printing surface of the balloon to planar;

3) Balloon ink requires a very good flexibility and quick-drying;

4) It is clear that the balloon does not belong to a high-definition screen printing screen printing, due to its process is characterized, for the quality can not ask too much

Why installed pad clean device on pad printer?

In the eyes of pad printing operatives, cleaning pad is an essential job: Use cloth dipped with solvent and clean rubber pad surface residual solvent inks.

Although this work is simple, but there are some side effects: First, reduce the life of rubber pad , and the second for the operation of the workers have some skin damage. The installation of automatic cleaning pad printing machine is an effective means of avoiding the two side effects.

Automatic cleaning rubber pad is actually in the process of rubber pad bounced once in the constantly moving in adhesive tape above and then dipped in ink. Action than monochrome printing machine complex.

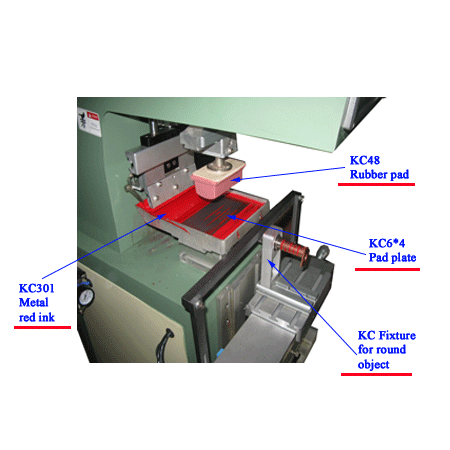

Round objects can be printed by pad printer?

The pad printing machine mainly prints irregular planes, but the pad printing machine can also print round or elliptical surfaces if necessary procedures are used to set up and install rotating fixtures.

The action procedure of the surface pad printer is as follows:

1) After the rubber head is inked, it is moved forward and pressed down;

2) The product shuttles with the table and rotates;

3) After the rubber head is on the stage, return to the position of the steel plate and proceed to the next procedure.

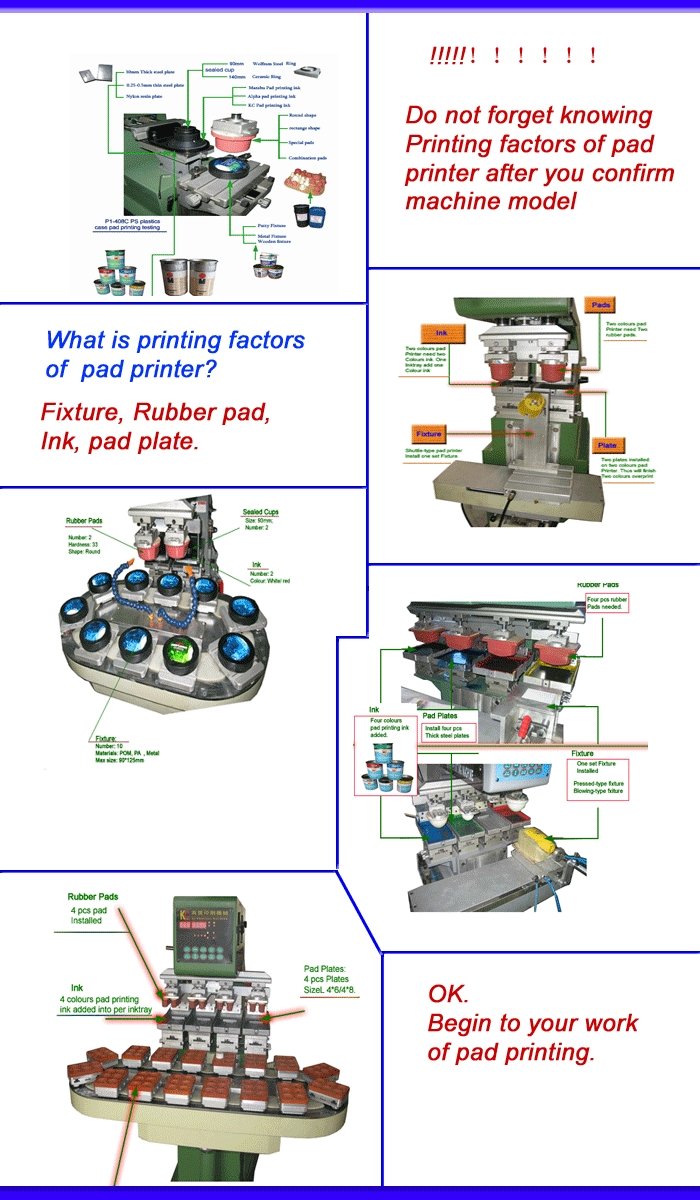

Do you know printing elements of pad printer?

The pad printing machine has an unusual adaptability, especially its practicality for the shape of the product is unmatched by any other printing process. More and more users are buying pad printing machines from China to print their products, such as stationery, cups, gifts, promotional items, electronics and toys.

But the pad printer can be printed without it, it must have complete printing elements to work. For beginners, expressing their intention to print to suppliers and requiring suppliers to provide complete printing solutions is the main form of less detours. Here, we will make a complete introduction to the printing elements of the pad printing machine:

1) Fixture: A device that fixes the product and mounts it on the workbench. We call it a fixture. The fixture has the same function of keeping the product in the same direction and fixing the printing position. Monochrome pad printing machines and all shuttle pad printers require a set of fixtures. The rotary pad printers require 10 sets, 16 sets, 20 sets and other different numbers of fixtures. The fixtures can be made of putty or metal materials or Non-metallic materials are processed.

2) Steel plate: Beginners can purchase steel plates by purchasing materials themselves, or they can ask suppliers to make steel plates according to the design patterns provided. There are several sets of oil pans or oil pans on the machine, which require several sets of steel plates. Of course, multi-color pad printing machines can prepare the number of steel plates as needed if printing less colors.

3) Pad printing head: Pad printing head making is also a complicated process. It is common for beginners to directly purchase plastic heads of different shapes. If you feel that the factory has expanded in size, or feel that it is not convenient to buy plastic heads, you can also try to make your own plastic head.

4) Ink: Ink must be purchased, you can buy it at your local dealer, or you can buy it directly from China.

When your pad has the above printing elements, you can start your printing task. The printing technology itself is not difficult. I believe that after your continuous exploration, you will become an expert in printing technology.

What is Pad printer?

The pad printing machine first appeared in Europe, and the “pad” was used to transfer the pattern on the plate, so it was called “Pad printer.” It was actually an indirect printing method. Pad is an intermediate carrier made of silicone rubber. It should be called a plastic head printing machine. However, this method of literal translation is not enough image, and Hong Kong practitioners first translate it into a pad printing machine.

The pad printing head is very soft and easily deformed, so the pad printing machine is very suitable for injection molding products with complicated shapes. At present, there are more than 30 factories in China that produce pad printing machines. The more famous brands are KENT, WINON, Etc.