|

|

|

|

Automatically cylinder screen printer

Model No.︰

S-VR12UV

Brand Name︰

LC

Country of Origin︰

China

Unit Price︰

US $ 24705 / pc

Minimum Order︰

1 pc

Product Description

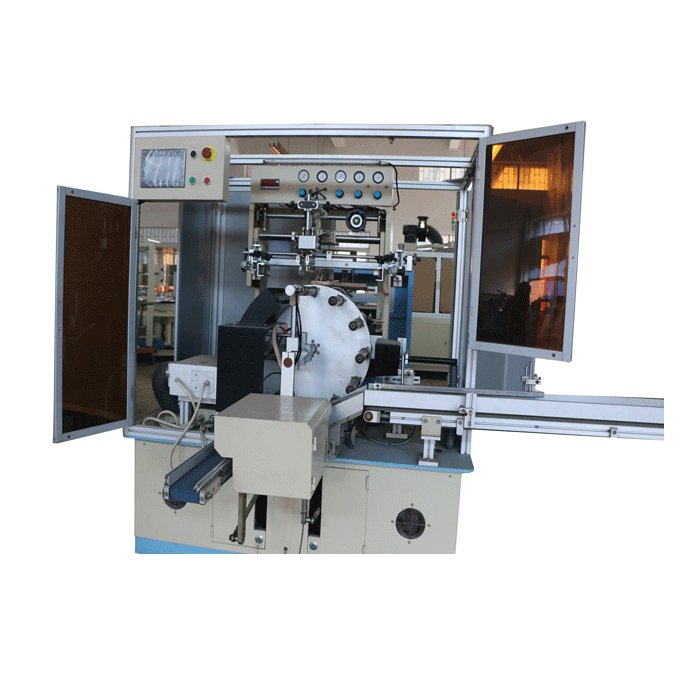

Automatic vertical turntable screen printer:

Workflow

• Prepress processing: Place the items to be printed on the corresponding station of the vertical turntable. The turntable drives the items to rotate to the prepress processing area, where operations such as surface cleaning and coating pretreatment can be performed to prepare for subsequent screen printing, ensure better adhesion of ink, and improve printing quality.

• Automatic screen printing: After prepress processing, the turntable transfers the items to the screen printing station. The screen printing system starts working, and the scraper moves on the screen printing plate to transfer the ink evenly to the surface of the item through the mesh to form the required graphics. This process relies on automatic control and can be completed accurately and efficiently.

• UV curing: After the screen printing is completed, the item comes to the UV curing area with the turntable. The UV lamp emits ultraviolet rays of a specific wavelength to irradiate the printed surface, so that the ink quickly dries and solidifies, ensuring that the pattern is firm and the color is long-lasting. The curing speed is fast and can be matched with the high-speed printing process.

• Automatic unloading: When UV curing is finished, the turntable continues to rotate and delivers the printed and cured items to the unloading position. The automatic unloading device will remove them in order to complete the entire printing process. Then the turntable can accept new items to be printed, and the production cycle is repeated for efficient production.

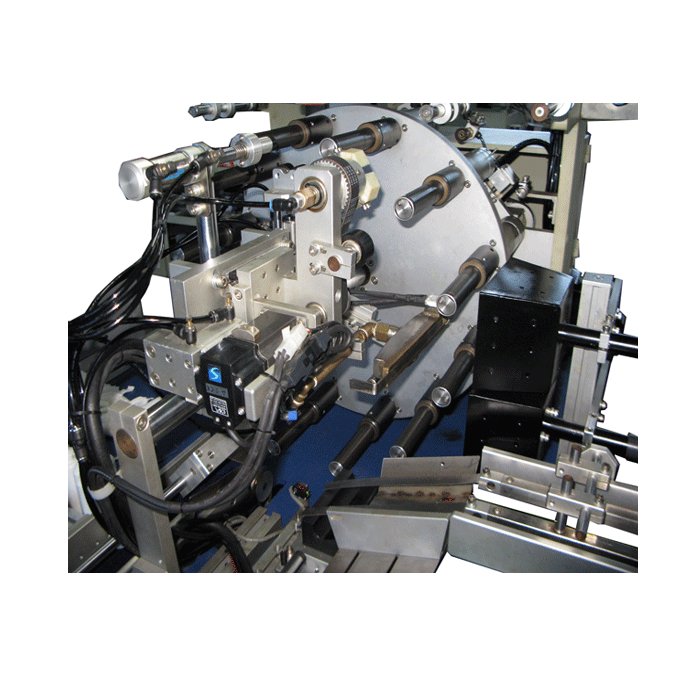

Main structure and features

• Vertical turntable: As a core component, it carries multiple workstations. Through stable and precise rotation, it can orderly transport items to different processing areas to ensure that each process is closely connected and smooth, and can adapt to items of different shapes and sizes. Fixing is achieved by replacing or adjusting the fixture.

• Screen printing system: includes key parts such as screen printing plate, scraper, and ink supply system. There are pre-made graphic parts on the screen printing plate. The scraper is responsible for scraping the ink from the ink tank to the printing plate and causing the ink to pass through the mesh. The ink supply system ensures the continuous and stable supply of ink during the printing process.

• UV curing system: It consists of UV lamps, reflectors, cooling devices, etc. UV lamps are the key to generating ultraviolet rays. Reflectors can improve the utilization rate of ultraviolet rays, so that the surface of objects can be more fully irradiated. The cooling device prevents the equipment from malfunctioning due to high temperature during long-term operation, ensuring the curing effect and equipment stability.

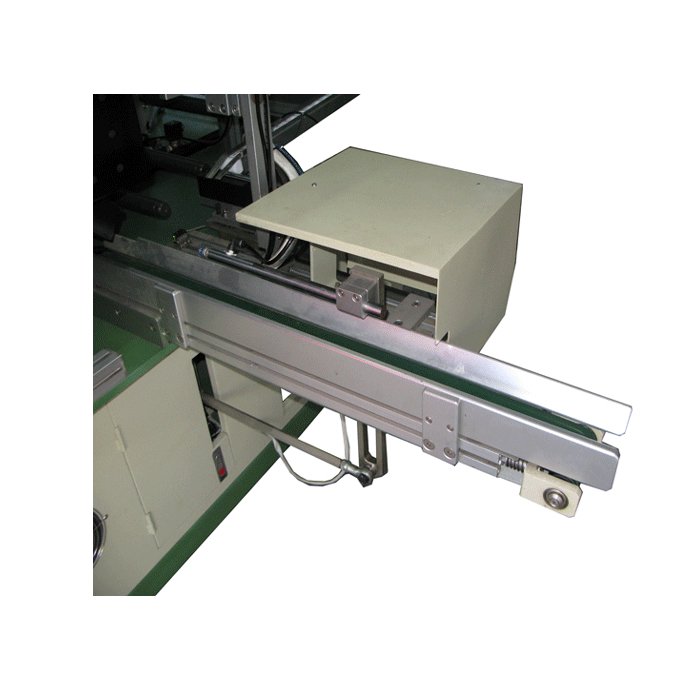

• Automatic unloading device: It can be in the form of a manipulator, conveyor belt, etc., which can accurately and quickly remove the printed objects from the turntable and convey them to the designated position, reducing manual intervention and improving production efficiency.

Advantages

• High speed and high efficiency: Each link is automatically connected, reducing the intermediate pause time, and can complete the printing of a large number of objects in a short time, meeting the needs of large-scale production, and greatly improving production efficiency.

• High printing quality: Pre-press processing ensures the adhesion effect of ink, automatic screen printing can accurately control the printing parameters, and UV curing allows the ink to cure quickly and firmly, making the overall printed pattern clear, colorful, and stable in quality.

• Comprehensive functions: It covers the complete screen printing process such as pre-press processing, screen printing, curing, unloading, etc. One device can complete multiple processes without the need to configure other equipment for cooperation, saving space and cost.

• Wide range of applications: By properly adjusting relevant components, it can print on objects of various materials, shapes and sizes, such as plastic products, glass products, paper products, etc., and can meet the printing needs of different industries.

|

S-VR12UV Full automatically Soft-tube screen printing machine/Structure |

|

|

Feeding device |

Conveyor, customized feeding system |

|

Direction identification |

Sensor, automatically identification |

|

Surface treatment |

Flame treatment, automatically lights |

|

Working table |

12-station stand rorating working table |

|

Actions |

Precision indexing disc Rotating transport |

|

Max Printing diameter |

70mm |

|

Max Printing Length |

200mm |

|

Rubber squeegee controlling |

High precision guide shaft |

|

Ink drying device |

UV Dying system |

|

Discharging |

Conveyor |

|

S-VR12UV Automatically Soft-tube screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

S-VR12UV Full automatically screen printing Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

S-VR12UV One color full automatically screen printing machine//Advantage |

|

|

Function |

|

|

Main configuration |

|